Werner Electric Supply unveils its Multifunction Instrument Asset (MIA)

MIA – New Innovative Process Control Trainer

MIA – New Innovative Process Control Trainer

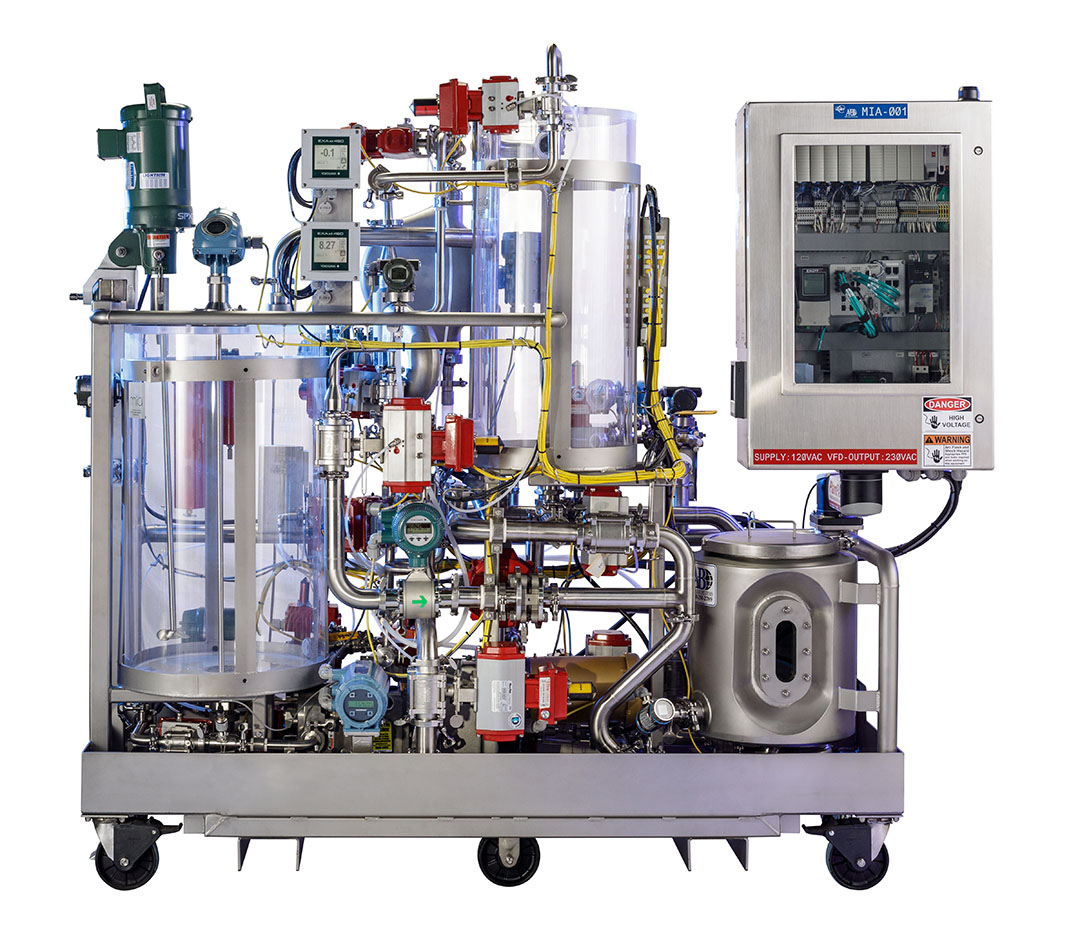

MIA, (MEE-ah) stands for multifunction instrument asset, and is an innovative process control trainer developed by Werner Electric Supply which can simulate the many processes found in manufacturing plants. MIA is an 82″x 26″x 80″ mobile unit which can be utilized for customer, college, and high school student automation process control training. The trainer was designed by Rodney Howard P.E., Werner Electric Supply product manager for process controls, with design recommendations from the International Society of Automation (ISA). The ISA is a leading global, nonprofit organization with more than 40,000 members worldwide and a training partner to Werner Electric. Many of the instruments that make up MIA were generously donated by Werner Electric’s vendors.

Video Courtesy of Red Shoes Ink

Werner Electric will use MIA to help train customers, students, and others about the intricacies of process controls, including pressure, flow, level, temperature, pH, conductivity, clean-in-place and so much more. MIA is an ideal asset and training tool for the next generation of process control professionals in industries such as food and beverage, advanced manufacturing, and pulp and paper, among others. For students who have an interest in manufacturing, engineering, or whatever it may be, bringing them to Werner Electric and giving them a hands-on opportunity to get training on MIA will give them a bit of a feel for what they might be getting into and the broadness of the field of process controls.

Werner Electric will use MIA to help train customers, students, and others about the intricacies of process controls, including pressure, flow, level, temperature, pH, conductivity, clean-in-place and so much more. MIA is an ideal asset and training tool for the next generation of process control professionals in industries such as food and beverage, advanced manufacturing, and pulp and paper, among others. For students who have an interest in manufacturing, engineering, or whatever it may be, bringing them to Werner Electric and giving them a hands-on opportunity to get training on MIA will give them a bit of a feel for what they might be getting into and the broadness of the field of process controls.

MIA can simulate nearly any type of process control automation. It can even simulate a malfunction in equipment to help trainees get hands on troubleshooting, imitating near real-life experience and situations they will run into in the field. The process control industry is a hands on industry and it’s very difficult to teach someone how to walk up to a transmitter and to set it up properly. An instructor may be able to teach someone conceptually how to do that, but having a hands-on tool such as MIA is invaluable.

So how exactly does MIA work? The instructor programs MIA for whichever scenario is being simulated, for example the cheese making clean in place process. MIA will have an operator graphic that displays temperature, pressure, flow, level, and batch control scenarios. The graphic will show the trainee what is happening and if something is going wrong. Being that MIA is fully automated and connected through the internet of things (IoT) it can be monitored from computers, tablets, and even cell phones to ensure the process is occurring correctly.

All of this process technology is used in operating plants today… and MIA is built with the latest state of the art components. To see more on how this new innovative technology works, watch the Werner Electric Supply Multifunction Instrument Asset video (link video here?).

For more information on Werner Electric Supply or to learn more about MIA, visit www.wernerelectric.com, or contact Werner Electric process control manager Rodney Howard at rhoward@wernerelectric.com.

The Werner Electric Supply Multifunction Instrument Asset video courtesy of Red Shoes Ink.